History

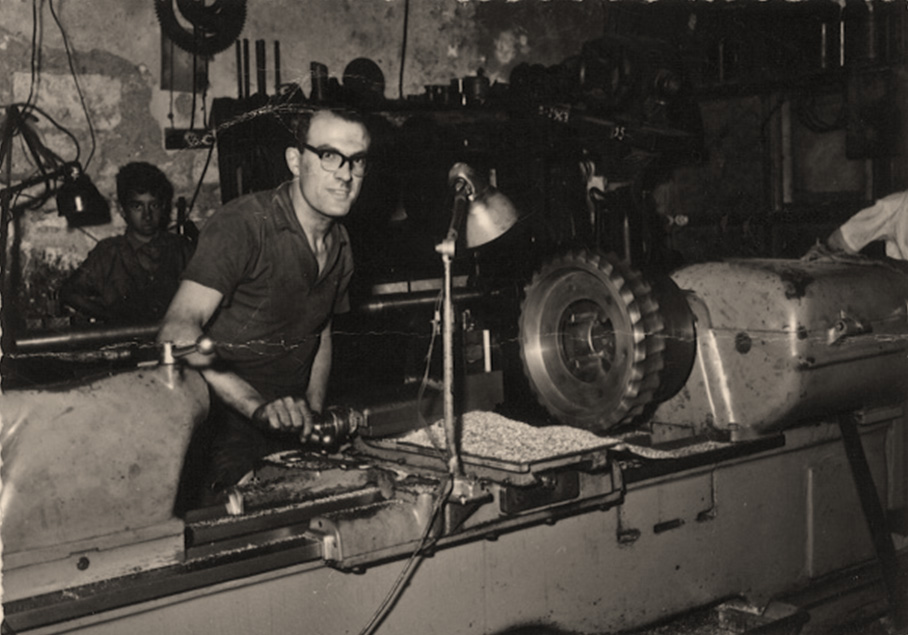

Officina Gigotti was founded in June 1968 as a mechanical tool shop specializing in the construction and repair of mechanical components and organs for the motor fishing sector. It was founded by Gigotti Francesco himself who, after his experience as an employee of some local mechanical companies, decides to put his professionalism at the disposal of local shipyards and boat builders (shipwrights).

1970

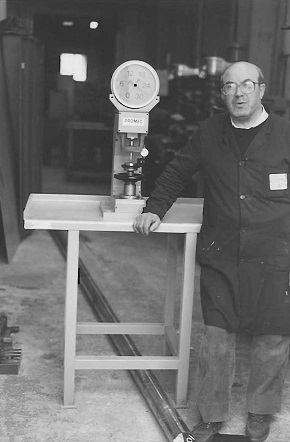

From the early 70s to 78, GIGOTTI stands out for the production of components and spare parts for hydraulic breakers taking part in the SAMOTER fair in Verona, leaving an important “sign” among local producers.

1978

One of the steps that will mark the evolution of GIGOTTI takes place at the end of the 1970s when the supply relationship with important local industries such as: Pirelli Meridionale Cavi di Giovinazzo, Oto Trasm, Oto Melara, RIV-SKF, Weber Altecna, Isotta begins. Fraschini, Breda Southern Fucine of Modugno. In the same period, the first scheduled supply contracts were signed with a leading company in the sector of transmissions with Levi Drive Unit surface propellers (inboard boats).

The important orders acquired will soon lead GIGOTTI to develop a “know-how” in the transformation processes of metals and non-metals such as to allow it all the series of technological investments that will determine its success in the years to come.

1982

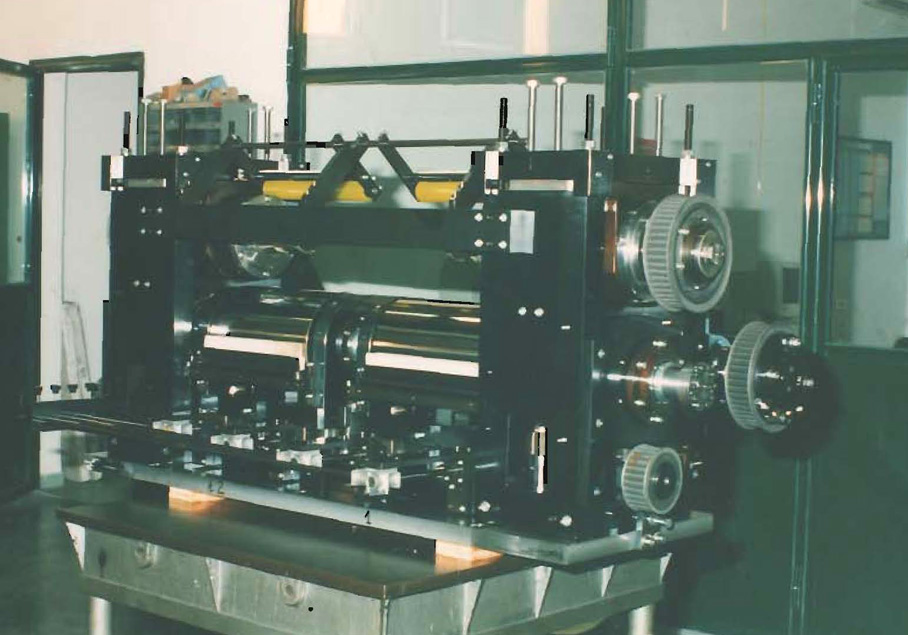

In 1982 GIGOTTI successfully proposed itself as a partner for the production of precision mechanics in the field of automatic systems and custom equipment for the automotive sector, collaborating with major national manufacturers of international fame such as COMAU, GEFIT, PFM.

Following the continuous and growing demand for new applications and an improved production capacity, in this period GIGOTTI purchases its first two Continuous Numerical Control (CNC) machines, the first is a DAINICHI lathe equipped with a tool holder turret with 12 positions. and the second a RAMBAUDI cutter equipped with a mobile bed and manual tool change. These two machines will represent the beginning of a new era of investments aimed at guaranteeing a production capacity aligned with the needs of the constantly evolving market, a fundamental aspect that has always characterized the GIGOTTI Group.

1984

In 1984 GIGOTTI collaborated with the Laser Center of Valenzano and with the Elasis Motor Power Research Center of Bari and Pomigliano d’Arco, providing a fundamental contribution to the experimental and pioneering phase of the development of the Common Rail system by creating the first prototypes of injectors and various equipment and instrumentation for the study and research on sprays produced by Diesel injectors (Experimental Investigation of Sprays). In the same period and until 1990 it establishes new supply and collaboration relationships with various technical offices (DIAMEC / MASMEC, PROMEC SUD, CMA, etc.) local oriented to the design of equipment and machines for the local automotive: Magneti Marelli, Firestone, RIV -SKF, Weber Altecna.

In the same period, GIGOTTI undertook important commercial relationships with important Italian manufacturers of automatic packaging machines and with a Swiss manufacturer of automatic machines for the production of wristwatches.

1990

The early 90s are the years of technological maturity marked by strategic choices that involve the orientation towards a different clientele that is certainly more demanding and which at the same time offers GIGOTTI the opportunity to demonstrate its ability to create and manage complex supplies. which require a completely different organizational structure and mentality. The results obtained with the new strategy reinforce greater awareness of the value of the service and the quality of the mechanics created, motivating the launch of GIGOTTI in a national and subsequently international market, effectively leaving the local spare parts market to a large number of small local workshops. founded largely by former collaborators, of whom Gigotti has always been proud.

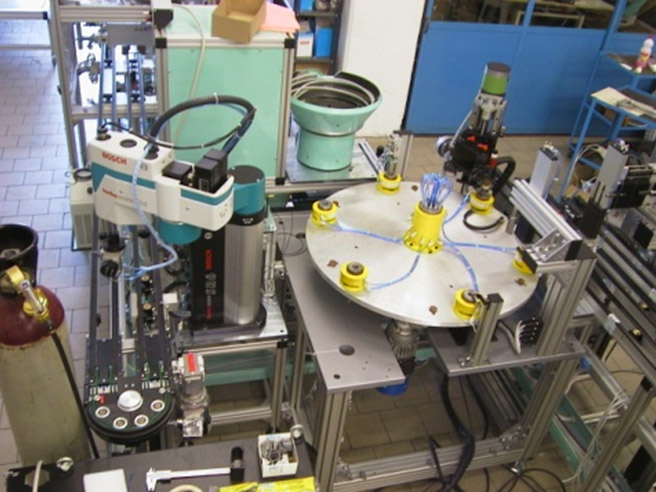

In recent years, GIGOTTI has consolidated numerous supply relationships in various sectors:

- machines and systems for wrapping and packaging (food and no-food)

- machines for the production of capacitors

- machines for the production and packaging of cigarettes, production of filters, other tobacco products

machine tools and transfers - machines for flat glass processing and for the production of glass containers

- machinery for the production of disposable hygienic products

automation and robotics for the automotive sector

1998

Towards the end of the 90s the growing number of customers and the increased needs pushed towards the birth of a new investment plan both in machinery and in human resources. The new headquarters were built in the industrial area of Molfetta (one of the very first production sites in the new industrial area) and the entire production was transferred here.

1999

It is in these years that GIGOTTI concretizes the idea of founding A&D to satisfy a series of requests coming from the automotive sector and from some market niches that require the design of customized solutions to produce: production of electrical cables, production of polyethylene pipes, molds for plastic materials, equipment for production, systems for the medical and biomedical sectors, research centers and small businesses oriented towards placing new products on the market. The A & D settles in the old factory in ss.16 dir. Bisceglie at km 775 + 600.

2003

MECCANICA GIGOTTI was founded in 2003 and moved to the new factory built in lot da-2 next to that of OFFICINE GIGOTTI FRANCESCO.

In the same period GIGOTTI certifies its production process according to the ISO 9000 standard at the same time throughout the group of companies.

The certification will initiate a new organizational structure aimed at guaranteeing its customers the 4 pillars of supplies:

- Quality

- Delivery time

- Competitiveness

- Pre and post sales assistance

2005

GIGOTTI decides to also transfer the A & D to the industrial area of Molfetta to complete the range of supply services offered by integrating the design, on the same occasion new areas are set up to expand the raw materials warehouse and that of finished products.

From this moment on, the organizational structure consolidates the synergies between the three companies and obtains the best performance in the supply of Design, Construction and Assembly, gaining considerable interest and success also abroad. The procedures for the complete management of the export phase, transport, customs clearance, storage of the goods up to delivery to the customer are acquired.

2008

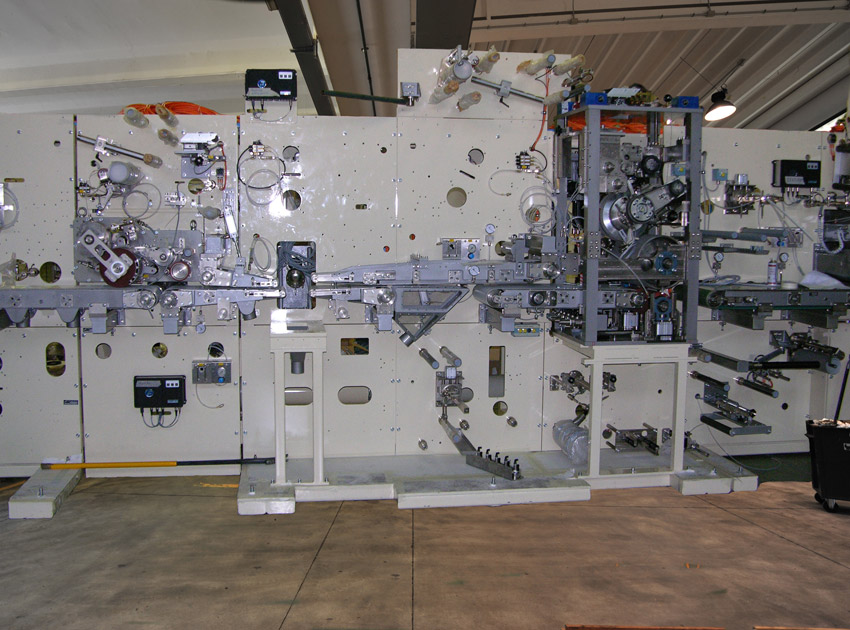

In 2008, a strategic investment plan was implemented aimed at expanding the production capacity that positions GIGOTTI as a grade A supplier for the supply of complex mechanical units for a multinational company.

2010

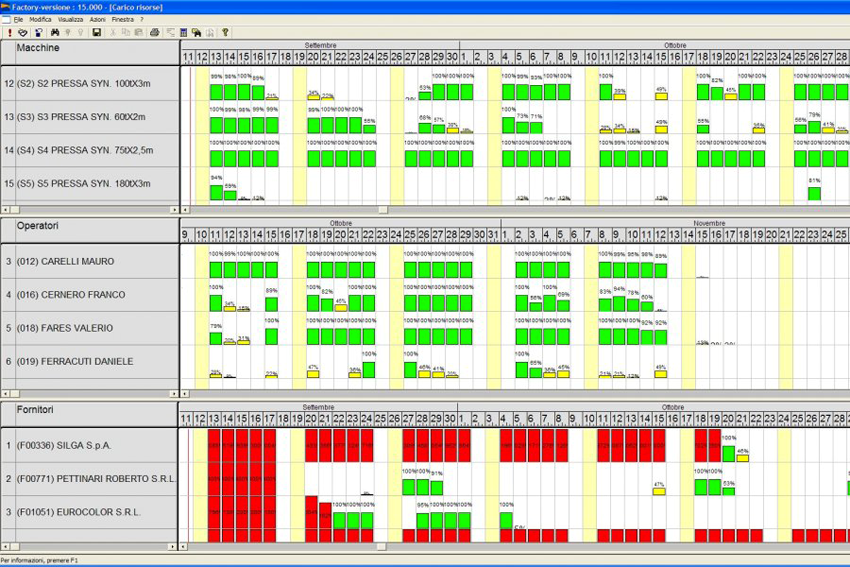

In 2010, the complexity of the supplies and the management characteristics highlight the need to share process and management information more quickly and in all company areas by limiting the use of paper.

GIGOTTI decides for a substantial organizational change by implementing an innovative customized integrated information system within the group that allows real-time access to all technical and process information at any stage, monitoring the progress of the work, planning the workload and manage unexpected events in compliance with delivery times.

2012

In 2012 GIGOTTI matures in its new vision an internationalization project and at the same time the need to expand and innovate the production process with an investment plan in machinery and technologies aimed at further raising the quality of supplies and reducing lead-times.

Add value

to your projects

Backed by half a century’s experience and a deep-rooted culture of quality and innovation, GIGOTTI is a first-rate technological partner and boasts a consolidated long-standing relationship with several prestigious industries, machinery and plant manufacturers of international fame.