SKILLS

The key to our success BFC (Better – Faster – Cheaper)

Technical competence in internal and external processes

Since our foundation in 1968, our philosophy has been based on quality and innovation. Our specialization in precision mechanical machining for the production of complex components and in the construction of assembled groups and customized machines offers our customers the opportunity to focus on the innovation and development of their products and on sales in the global market.

The constant improvement of business processes and cooperation in business networks along the added value chain allows us the best partnership with the world market leaders in the construction of plants and machines in various sectors. This translates into a concrete competitive advantage that can be found in terms of:

Total quality management

- The quality of all products is ensured through the use of systematically calibrated and calibrated measurement systems; three-dimensional measuring system are placed in an air-conditioned room set up in correspondence with the processing department:

- Exceed customer expectations

- Keep the motivation and professionalism of our staff

- high ensure process-oriented quality continuous improvement

- process error-free

production on the first piece

Certificato secondo: ISO 9001:2008

Delivery time

Management of orders in real-time, planning and monitoring of progress

Assembly of machines and groups in small quantities

The high flexibility of our technicians and their competence on assembly standards allow us an efficient and fast production of machines and groups in small quantities. Here, too, process innovation is in first place. Assembly and logistics systems are dedicated and specific to products and customer needs.

Serial production of machines and groups

The PULL, KANBAN, One-Piece-Flow principles are adopted for the production of machines and groups.

This leads to a significant reduction in warehouse and waste, the involvement of production and the supply chain allow us to obtain shorter delivery times.

Productivity

High competence in processing

The effective use of modern production systems is the basis for competitive production. The production of components in small quantities and small series is carried out with more than 45 machine tools. On average 4% of the annual turnover is invested in the modernization of the machines.

The adoption of modern CAD / CAM systems allows you to support and integrate the programming of the tool path and the creation of specific equipment.

Fundamental strategies for processes

- Continuous updating on the technological state with targeted investments in latest generation machinery

- Teamwork oriented process

- Definition of clear and specific objectives

- Empowerment of employees

- Sharing of information and transparency in communications

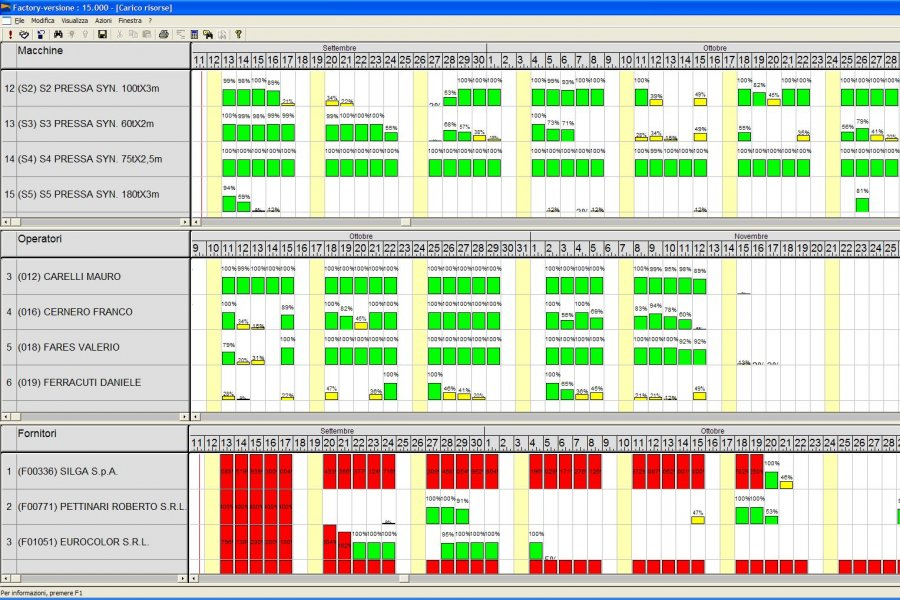

Production capacity

The management of production capacity and therefore of production is based on a dedicated computer system integrated with all company functions (Production, Purchasing, Customer orders, Warehouse, Human resources, Accounting, Quality) able to keep the production process under control. , ensure compliance with the Customer’s specifications at every stage.

All the production data concerning the single phases and the material used are reported in electronic format by means of a barcode coding system, which allows for absolute process traceability in real-time.

The management system is equipped with a network with numerous ADVANCED TERMINALS for data collection in production and is equipped with a finite capacity scheduler (appropriately parameterized by GIGOTTI) that allows you to plan and monitor the progress of production to guarantee the customer the expected deliveries. (insert photo scheduler and resource loading, data recording stations in production)

The materials on which the company is able to work are:

- Special construction steels (case-hardening, nitriding, quenching and tempering, spring steels, bearing steels,)

- Tool steels (hot and cold uses)

- Rapid steels

- Chrome bars

- Stainless steels (martensitic, austenitic, heat resistant)

- Cast iron (gray cast iron, nodular cast iron, mechanical cast iron)

- Aluminum, bronze, brass and alloys

- Industrial plastic, polymeric and thermoplastic materials.

Add value

to your projects

Backed by half a century’s experience and a deep-rooted culture of quality and innovation, GIGOTTI is a first-rate technological partner and boasts a consolidated long-standing relationship with several prestigious industries, machinery and plant manufacturers of international fame.